Accepted for publication in IEEE Robotics and Automation Letters (RAL), 2022

Description:

Robot kinematics is a fundamental basis for robot control. The kinematic model finds the relationship between actuation space (mtor/joint values) and Cartesian space (robot’s 3D position and orientation).

Generally, for serial-link rigid robots, geometric approaches (e.g. Denavit-Hartenberg convention) are sufficient to obtain accurate an kinematic model. However, robot designs are becoming more and more complex, especially in fields like minimally invasive surgery, where high degree of articulation and miniaturization are required.

Due to the increasing modelling complexity, machine learning, like Artificial Neural Networks, has become very useful for robot modelling. Generally two approaches are used:

- Inverse Kinematic (IK) modelling: the inputs are the desired robot’s poses to reach and the outputs are directly the robot’s motor commands;

- Forward Kinematic (FK) modelling: the inputs are the motor commands and the outputs are the robot’s poses.

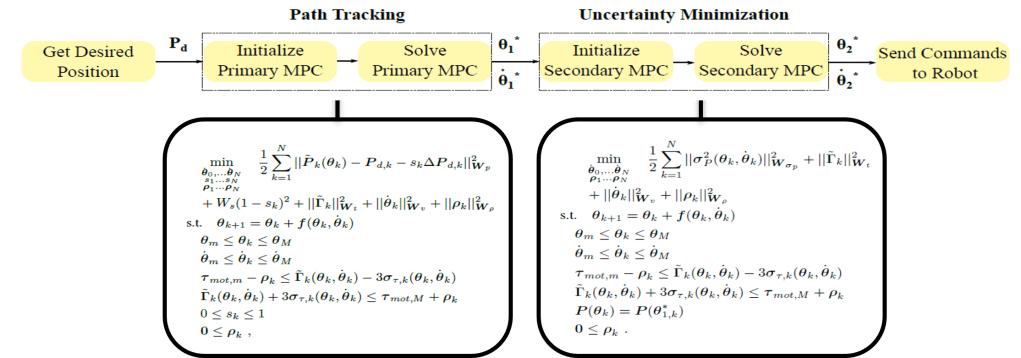

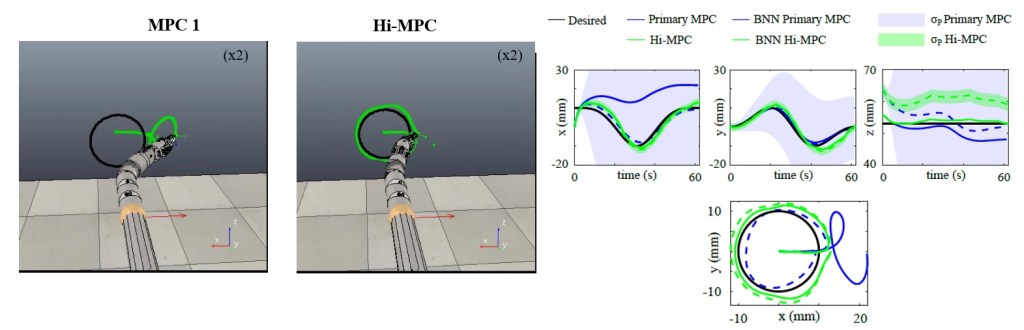

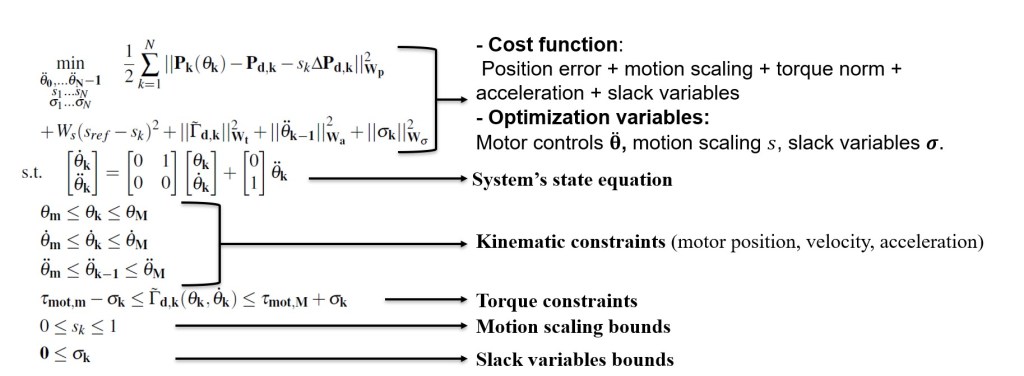

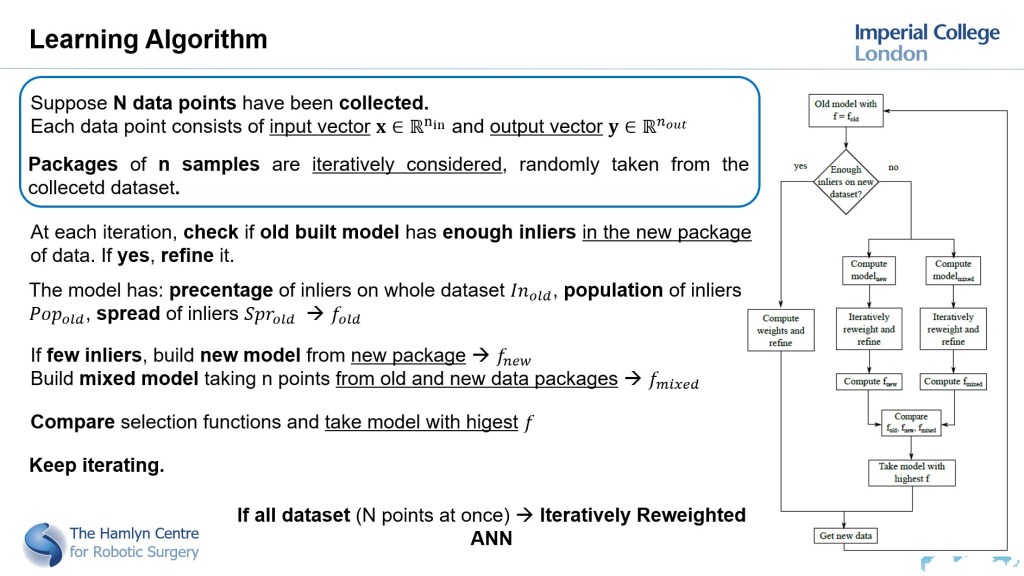

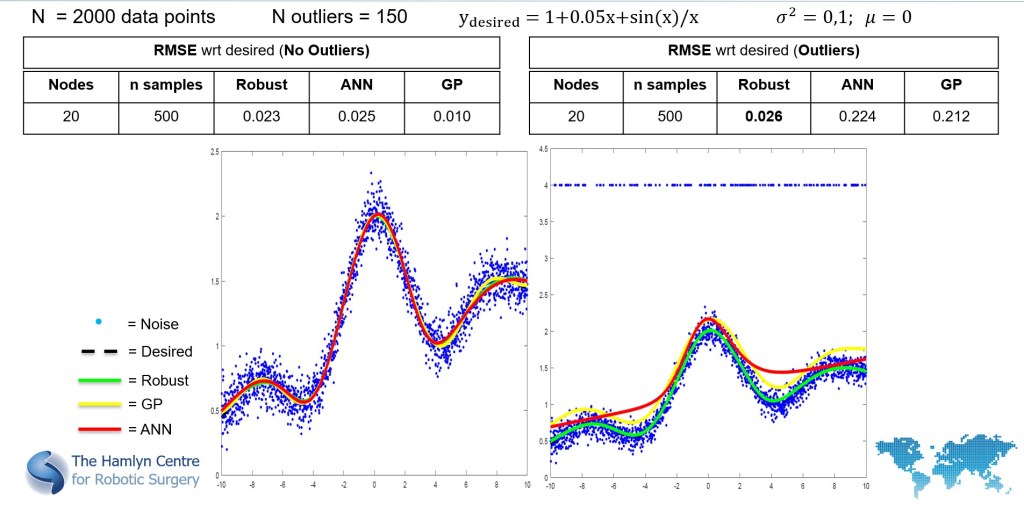

Learning the IK allows directly obtaining the robot’s commands, but the output only depends on the training strategy and data. When learning the FK, instead, the robot model can be used in consolidated optimal control approaches (like MPC, QP, etc) that guarantee better system’s stability and allow finding optimal control values for a given task.

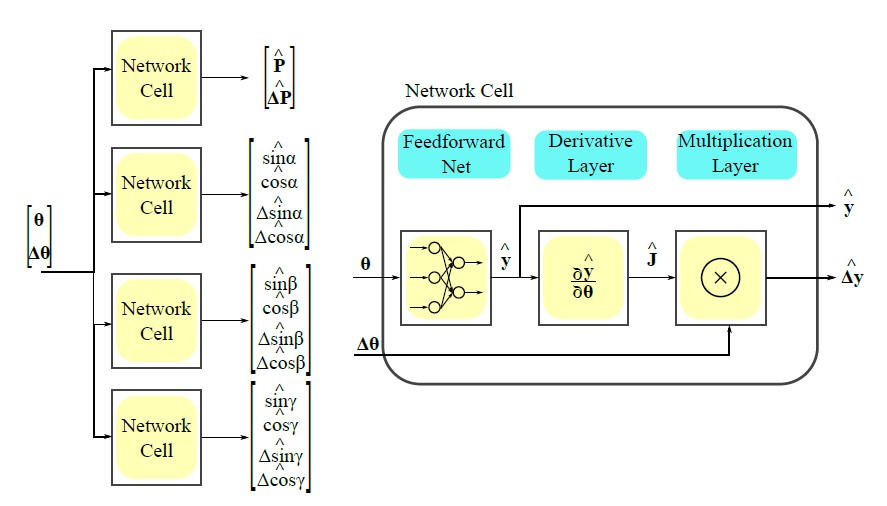

The drawback of learning the FK is that derivatives of the model are needed for control purposes and, in general, robot model learning does not consider differential relationships during model training.

Additionally, when the orientation is considered, a proper representation is needed in order to ensure continuity in the model to be built.

In this work we present AugNet, a neural network model that includes differential relationships during model learning for full robot pose (both 3D position and orientation). Additionally, we propose a feasible representation (trigonometric representation) for the orientation to overcome the challenges due to model discontinuities.

Our results show that including differential relationships during model learning allows improving robot model’s accuracy and control performance. Additionally, our trigonometric representation proves feasible in learning orientations.

In our work we employed Roll, Pitch, and Yaw angles. The main limitation from the control perspective is the possibility to encounter singularities due to Gimbal lock.